REC Solar pioneered half-cut solar photovoltaic cells in 2014, with the goal of increasing the energy production of solar panels. We’ll go over how they function in more detail later, but think of a half-cut cell as two different panels in one.

Trends in panels have a way of catching on rapidly. Half-cells are the next big technology to enter the mainstream. According to the ninth edition of the International Technology Roadzmap for Photovoltaic (ITRPV), half cells’ market share will increase from 5% in 2018 to roughly 40% in 2028.

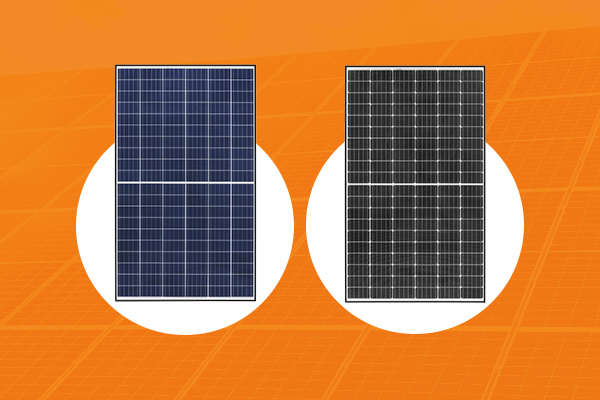

What are Half Cut and Twin Peak solar Panels?

They’re simple solar cells that have been halved into two. They have 120 half-sized solar cells instead of the 60 that ordinary roof panels have. As a result, there is less electrical resistance, which increases efficiency.

Half-cut solar panels also resist the effects of shade better than regular solar panels. This is due to the way the cells are linked together rather than the cells being sliced in two.

Several significant manufacturers believe that modern manufacturing techniques make half-cut solar cell panels worthwhile, notwithstanding the tiny improvement in efficiency.

One half-cell module in the Twin cell half-cell module series essentially transforms each panel into two twin panels. Because the cells are much smaller, the inter-cell space will not need to be as large, letting them be closer together.

This enables REC to divide the panel into two sections. The shading response is better when the upper and bottom module portions are independent. The upper half of a module will continue work if the bottom half is shaded.

Why Are Solar Cells Cut In Half & How They Work?

To reduce cell-to-module losses during assembly, solar cells are chopped in half. The square of the current time resistance is roughly equivalent to power loss. As a result, reducing a solar cell in half reduces power losses by a factor of four.

A typical solar panel consists of sixty 0.5V solar cells connected in series. Because voltages accumulate in series, this solar panel operates at 30 volts.

A solar cell that is split in half will produce half the current, but the voltage will remain the same. You’ll also have twice as many, so if half-cut cells were strung together like in a conventional panel, the voltage would be doubled.

Why Do We Use These Solar Panels?

1. Higher Price performance

It lowers the LCOE by halving the cost of the cells as well as the overall cost of a solar system (Levelized Cost of Energy). Modules with half-cut solar cells have the opportunity for speedier repayment times when compared to normal equivalents.

It makes the installation even more worth the upfront investment, especially for places where shadow cast and restricted areas are the main constraints. It is a cost-effective solution that does not require you to sacrifice quality or output.

2. Tolerance to Shade

A traditional solar panel typically consists of 60 0.5V solar cells connected in series. The 60 cells solar panel operates at 30V due to the serial addition of voltages. Half cut cells would provide half the current and double the voltage if linked together in a normal panel.

Manufacturers of solar inverters, who are striving to stay within the home solar voltage regulations, would not welcome this.

3. Fewer Hotspots

When one solar cell in a photovoltaic cell string is shadowed, the energy produced by the preceding unshaded cells can be dumped as heat into the first shaded cell. This creates a hotspot that, if left unattended for a long time, might harm the solar panel.

Only half as much heat is generated by twice as many panel cell strings. The reduced heat production should be less destructive to the panel, resulting in increased resistance to hot spot degradation and module longevity.

4. Power loss is reduced

One of the causes of power loss in a solar system is resistive losses. To combat this problem, dual cell panels boost the panel’s current conveyance. The 5-bar bus design inhibits electron flow in the circuit, increasing transmission while lowering internal resistance power. As a result, the rate of resistive losses is much lower than it should be.

5. Durability

Half-cut cells, in addition to having a higher energy production, are more durable, resulting in a longer life performance when compared to standard solar cells.

Half-cut cells are less prone to micro-cracks due to their more compact structure, which develop over time as a result of extended exposure to extreme weather conditions such as snow, hail, sun, wind, and extremely cold temperatures.

Half-Cut Panels the Future of Solar?

Half-cut cells are excellent for increasing the solar panel’s energy yield. Due to the larger number of cells and enhanced series wiring within the panel, half-cut solar cells outperform standard solar panels.

Traditional solar arrays can still be useful in many situations, such as if your roof receives plenty of sunlight throughout the day.

Half-cut cells, on the other hand, make sense if you need every ounce of energy you can obtain because you reside in a shady location or want to optimize your net metering benefits. If you have a tiny surface area and need to create as much solar electricity as possible, ask for half-cut cells.

Otherwise, standard panels should be enough, though they have their own shortcomings. Standard solar panels are not cost efficient and solar energy storage is expensive all while they take up a lot of space and sometimes have to be used in double numbers to make up for storing energy.

Conclusion

As long as the modules are suitably positioned along the route of shading, using half-cut twin cell cells can provide a significant benefit and increased performance in shaded settings when shading throughout a string is generally even, such as when produced by barriers such as other rows or walls. A large improvement in overall energy yield is possible when combined with other energy generating advancements in half cut cells, making the new panel a superior option for energy production on rooftops.

Novergy manufactures Very High Efficiency Crystalline Silicon solar panels with the highest quality materials and tight manufacturing standards. Their Half-cut Twin cell Solar panels deliver constant power and more kWh energy (up to 60% or more) over extended periods of time with less deterioration. Twin Peak Solar Panels come with a lot of advantages like –

(i) They are able to generate more solar power in less space thereby giving you a better space utilization and a complete peace of mind.

(ii) Twin Peak Solar panels bring in better performance during dusty environments and there is negligible or NIL impact on the performance.

(iii) Twin cell panels are also capable of delivering a superior output under high temperature and also under tropical conditions

Our solar panels are mechanically sturdy and approved to handle severe wind and snow loads, as well as being particularly responsive in low light settings, catching more sunlight in overcast conditions and generating more power. Because these solar panels have the lowest temperature coefficient, they produce more energy in tropical and high-temperature environments.

With its smarter and more durable construction, the twin peak solar panels effectively provide maximum throughput in all-weather situations.

Novergy solar panels come with a 25-year linear warranty, ensuring steady functionality and total peace of mind for the customer. In terms of long-term energy savings, it will be a reasonable investment.