What are half-cut Solar cells?

Implementing half-cut cells in solar panels can assist improve the power output of a solar panel system, just as bifacial solar panels and PERC solar cells improve the efficiencies of silicon solar panels. Half-cut solar cells are typical silicon solar cells that have been chopped in half using a laser cutter, as the name suggests.

Compared to ordinary solar cells, half-cut solar cells have a variety of advantages. Above all, half-cut solar cells perform better and last longer. In terms of performance, half-cut cells can boost panel efficiencies by a few percentage points. Half-cut cells are more physically resilient than their conventional counterparts, as they are smaller and less prone to cracking, in addition to having higher output numbers.

Let’s have a look at some other advantages of half-cut solar panels –

1. Cut down on resistive losses

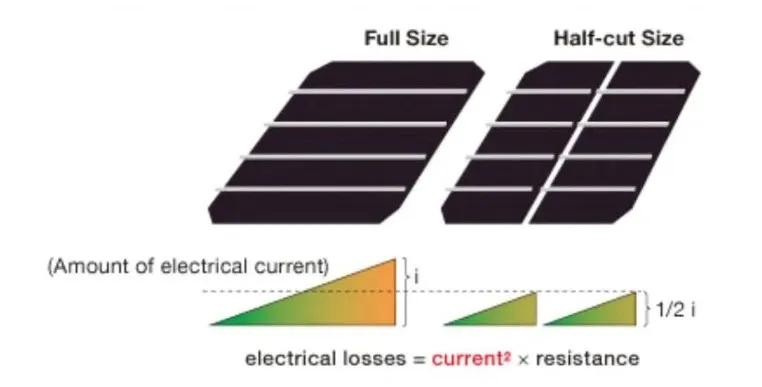

Resistive losses, or power lost during electrical current transit, is one form of power loss when solar cells convert sunlight into electricity.

The tiny metal ribbons that traverse the surface of solar cells and connect them to nearby wires and cells transmit current and transferring current via these ribbons results in some energy loss.

The current generated by each solar cell is halved when solar cells are sliced in half, and the lower current flowing leads to fewer resistive losses as energy passes through the cells and wires in a solar panel. As a result, to improve panel performance by reducing power loss.

2. Shade tolerance is higher:

Half-cut solar cells are more resistant to the effects of a shadow than traditional solar cells. This is due to the wiring procedures used to link half-cut cells in a panel, rather than the cells being cut in half.

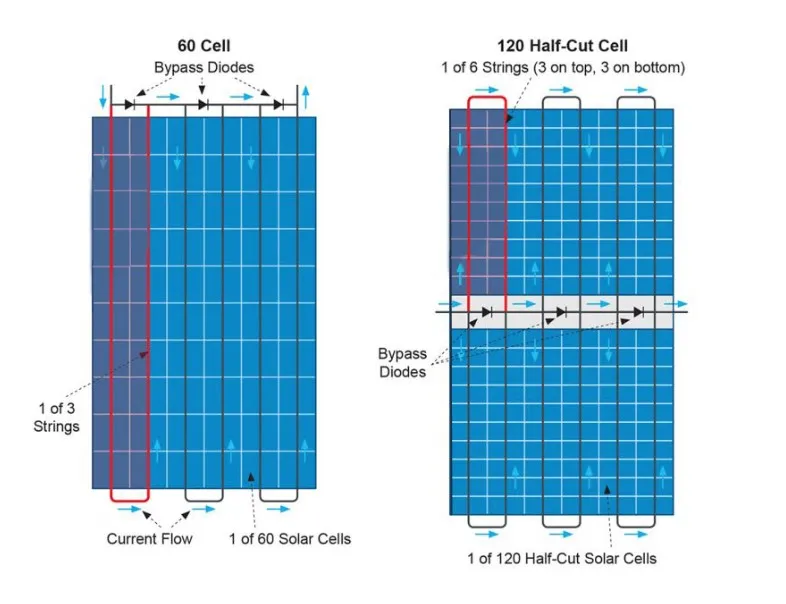

The cells of full-cell conventional solar panels are wired together in rows. It’s known as series wiring. If one cell in a row is shaded and not producing energy in a series wiring system, the entire row of cells will stop producing electricity.

A typical solar panel, for example, includes three cell strings, each of which can be bypassed with a bypass diode. One shaded cell will cause one-third of the panel to be turned off.

Half-cut cells, on the other hand, have the same wiring series. Half-cut cell panels, on the other hand, have doubled the number of cells (120 instead of 60). As a result, the number of cells in each row doubled.

When a single cell in a panel designed with half-cut cells is shaded, this style of wiring allows the panel to lose less power. The reason for this is that a single shaded cell can only reduce the entire panel power output by a sixth.

Because a half-cut solar panel contains six independent cell strings (but only three bypass diodes), it may tolerate partial shade better. The other half of the panel can still function if half of it is shaded.

3. Minimizing the damage while reducing the hotspots

When a solar panel cell string has one shaded solar cell, the energy generated by the unshaded cells can be released as heat into the first shaded cell. This produces a hot spot that, if ignored for a while, could damage the solar panel.

By doubling the number of panel cell strings, only half the heat is produced. However, because the shaded cell has half the surface area to dissipate heat as a regular cell, the total quantity of heat produced should be less harmful to the panel. As a result, it’s likely that resistance to hot spot damage may improve.

Why use Half-Cell technology in your upcoming installation?

Any sale of a rooftop PV system is driven primarily by the chance to increase electricity generation for your clients while also reducing their energy costs. Your solar installations could become more advanced thanks to half-cell technology.

Half-cells have become more and more popular over time for a variety of very clear reasons, including:

Excellent functionality in dimly lit environments

In low light conditions, half-cell technology is fantastic. Due to the architecture, the inverter receives greater power when there are more cells present.

Rising complexity

There are more potential failure sites within the module as a result of the higher cell count, including the cells themselves, the string connections, and the solder joints. These difficulties have been reduced in some measure by automation in the module production process.

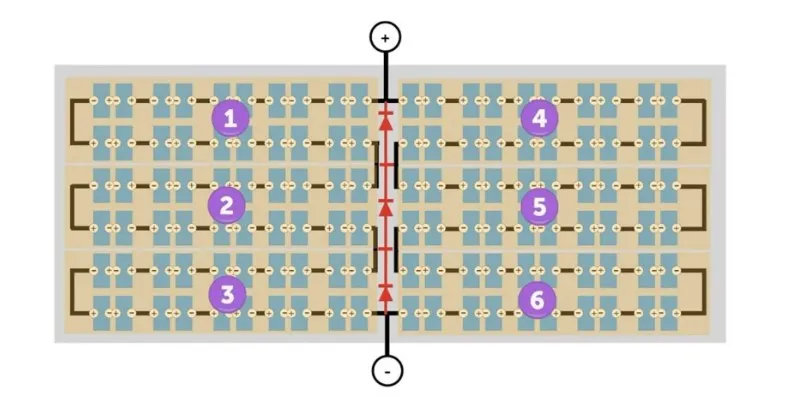

Concerns for installation

The junction boxes on conventional solar modules are at one end of the back of the module. Half-cut cell modules, on the other hand, contain two junction boxes with a positive and negative terminal in the centre of the module. There are associated orientation considerations for installers when using these sorts of modules, even though the cables are frequently long enough to connect the modules in either portrait or landscape.

Advantages of half-cut technology

Compared to full cell modules, half-cut cell modules have been shown to provide more electricity per square metre. Half-cut cells may be able to decrease the payback period and the Levelized Cost of Electricity of a system that decides to use this form of solar cell technology, similar to the comparison of PERC and Al-BSF cells.

Get Started with your Solar Journey

Novergy offers half-cut solar panels which are made from the highest quality raw materials and created under stringent manufacturing standards.

Multinational companies, industries and factories from across various domains trust Novergy as their preferred solar partner.

Interested in learning more about our Solar Solutions?

Schedule a call with our Solar Expert and get started with your Solar Journey with Novergy.