Harnessing solar energy has become a vital component of our quest for sustainable power sources. As the solar industry continues to evolve, different technologies have emerged to make the most of our abundant sunlight. Three of the most prominent contenders in the solar cell arena are Topcon, HJT (Heterojunction Technology), and PERC (Passivated Emitter Rear Cell) solar cells. Each of these technologies offers distinct advantages and disadvantages, making it crucial for consumers and industry professionals alike to understand the differences between them.

We’ll delve into the world of solar cells and explore the nuances that set Topcon, HJT, and PERC solar cells apart, helping you make informed decisions.

Comparison Between PERC Solar Cells and TOPCon Solar Cells Technology

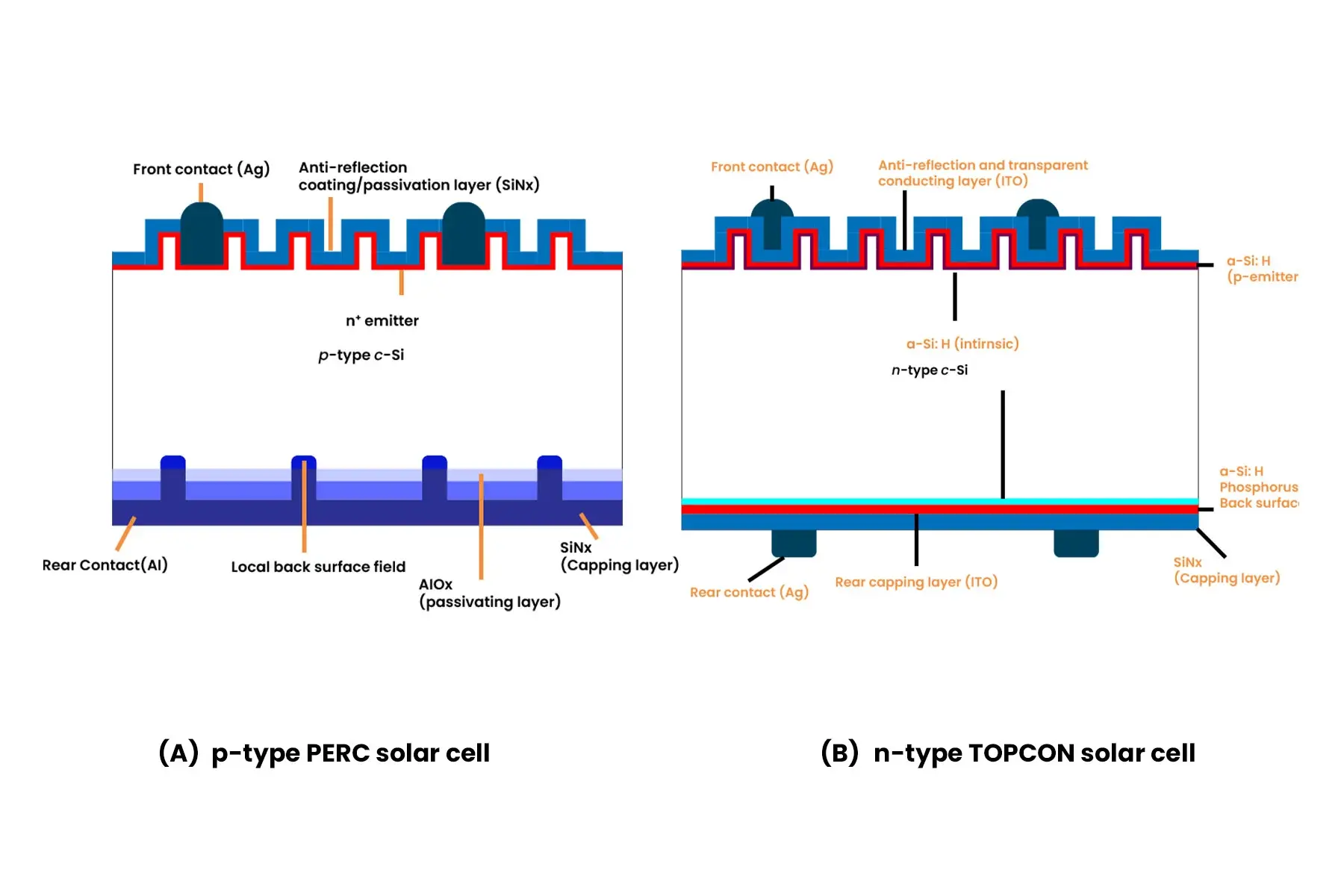

When comparing PERC and TOPCon solar cell technologies, it’s worth noting that visually, they appear quite similar once installed wi

thin a module. However, there are key distinctions between them. TOPCon cells are crafted from n-doped silicon, which is a more complex material to work with during manufacturing. Nonetheless, this material enables TOPCon cells to attain higher levels of efficiency.

Another notable contrast lies in the meticulous passivation process applied to TOPCon cells. While it presents technical challenges, this process delivers significant benefits. Specifically, the application of a polycrystalline silicon layer to the cell’s rear side demands substantial technical expertise. However, it enables the solar cell to withstand higher voltages, ultimately leading to a notable increase in overall efficiency.

Comparing HJT Solar Cell and TOPCon Solar Cell Technologies

HJT panels excel in efficiency and bifaciality, but their manufacturing is complex and costly, and they’re susceptible to humidity.

In contrast, TOPCon panels offer a simpler, cost-effective manufacturing process with reduced sensitivity to humidity, but they trade off some efficiency and bifacial performance when compared to HJT panels.

Topcon Solar Panel

TOPCon, “Tunnel Oxide Passivated Contact,” represents an innovative leap in solar cell technology. This cutting-edge technology is making waves in the renewable energy industry due to its unique structure and remarkable efficiency gains. In a TOPCon solar cell, a delicate tunnel oxide layer is strategically placed between two crucial components: a transparent conductive oxide (TCO) layer and a p-doped crystalline silicon layer.

The TCO layer serves as the front contact of the solar cell, allowing sunlight to pass through and interact with the underlying layers. Meanwhile, the p-doped crystalline silicon layer functions as the absorber layer, absorbing the solar radiation and converting it into electrical energy. However, what truly sets TOPCon apart is the tunnel oxide layer’s role as a passivation layer.

This passivation layer plays a pivotal role in preventing the undesirable recombination of charge carriers at the solar cell’s surface. By mitigating this recombination, TOPCon solar panels achieve a higher level of efficiency, maximizing their ability to capture energy from the sun per unit of surface area.

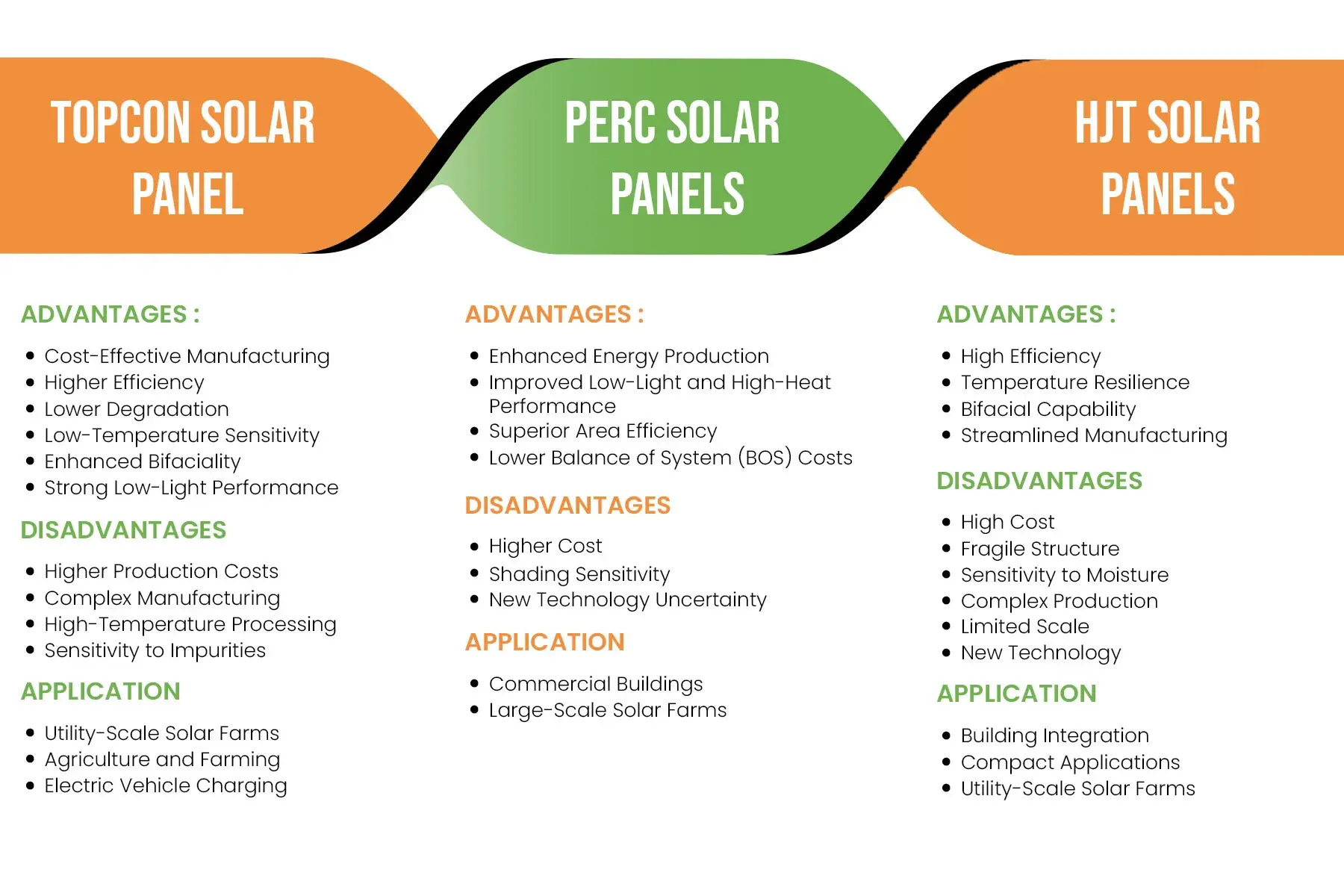

Advantages of TOPCon Solar Panels

- Cost-Effective Manufacturing: No need for expensive machinery, making large-scale production easier.

- Higher Efficiency: Up to 28% efficiency, surpassing PERC cells for more power generation.

- Lower Degradation: Longer lifespan with minimal power degradation over time.

- Low-Temperature Sensitivity: Maintains efficiency even in hot climates.

- Enhanced Bifaciality: Generates electricity from both sides.

- Strong Low-Light Performance: Efficient even in low-light conditions.

Disadvantages of TOPCon Solar PV Module Technology

- Higher Production Costs: Additional materials and complexity can increase production expenses.

- Complex Manufacturing: Challenging to scale production to meet high demand.

- High-Temperature Processing: Elevated energy consumption, emissions, and potential cell damage.

- Sensitivity to Impurities: Prone to efficiency reduction or failure due to material impurities.

Uses of Topcon Solar Panels

- Utility-Scale Solar Farms: These panels excel in utility-scale solar power plants, maximizing electricity production within limited space thanks to their high efficiency.

- Agriculture and Farming: TOPCon panels prove valuable in agricultural settings, powering water pumps, irrigation systems, and crop drying processes, offering off-grid energy solutions to remote regions.

- Electric Vehicle Charging: Leveraging their capabilities, TOPCon solar panels drive electric vehicle charging stations, promoting clean and sustainable transportation options.

Perc Solar Panels

In recent years, there has been a surge in the popularity of Passivated Emitter and Rear Contact (PERC) solar panels within the solar industry due to their ability to enhance solar power efficiency. These panels utilize PERC solar cells, an upgraded iteration of traditional solar cells. With their innovative design, they can produce 6 to 12 % more energy compared to their conventional counterparts.

The acronym PERC stands for Passivated Emitter and Rear Cell. The distinctive feature of a PERC solar cell is the presence of a passivation layer on its rear side, which plays a pivotal role in reducing recombination losses and boosting light absorption. Essentially, the rear-side passivation layer acts as a light reflector, preventing sunlight that passes through the silicon cell from escaping without absorption. This reflective capability provides the solar cell with a second opportunity to absorb the light, resulting in a significant enhancement in overall efficiency.

Advantages of PERC Solar Panels

- Enhanced Energy Production: PERC panels boast higher efficiency, leading to a potential 5% increase in energy production for an entire (PV) stands for Photovoltaic system.

- Improved Low-Light and High-Heat Performance: PERC panels excel in low-light and high-temperature conditions, delivering approximately 3% higher efficiency.

- Superior Area Efficiency: Thanks to their increased efficiency, PERC panels can achieve the same power output as traditional panels using fewer units, reducing the installation space required.

- Lower Balance of System (BOS) Costs: Fewer PERC panels can achieve equivalent output, resulting in reduced BOS costs, labor expenses, and soft costs like inverters and disconnects.

Disadvantages of PERC Solar Panels

- Higher Cost: PERC solar panels generally come at a higher price point compared to traditional panels.

- Shading Sensitivity: PERC panels are slightly more susceptible to shading issues than traditional solar panels.

- New Technology Uncertainty: As a relatively new technology, there may be some uncertainty regarding the long-term durability and performance of PERC solar panels.

Uses of Perc Solar Panels

- Commercial Buildings: Mono PERC solar panels find application in commercial structures like office buildings, shopping centers, and warehouses, helping cut electricity expenses and lower carbon footprint.

- Large-Scale Solar Farms: Mono PERC solar panels are deployed in utility-scale solar power plants, contributing to the generation of electricity on a grand scale.

HJT

Heterojunction (HJT) solar cell technology has emerged as a promising and relatively recent innovation in the field of solar cells, gaining significant traction in recent years due to its enhanced efficiency in converting sunlight into electricity.

Heterojunction solar panels are a specific type of photovoltaic panel characterized by a tri-layered structure, integrating two distinct technologies: crystalline silicon and amorphous “thin-film” silicon, synergistically optimizing electricity production.

HJT cells are composed of three key materials: Crystalline Silicon (c-Si), Amorphous Silicon (a-Si), and Indium Tin Oxide (ITO).

The initial layer, consisting of amorphous silicon, intercepts sunlight even before it reaches the crystalline layer, as well as any light that bounces off the underlying layers. The middle layer is composed of monocrystalline silicon, primarily responsible for converting the majority of sunlight into electricity. Finally, there is another amorphous thin-film silicon layer situated behind the crystalline silicon layer, capturing any remaining photons that have managed to penetrate the first two layers.

Through the harmonious combination of these two distinct technologies, heterojunction solar panels can harness more energy than either technology could achieve individually. These panels can achieve impressive efficiencies exceeding 25%, making them an increasingly attractive option for solar energy generation.

Advantages of HJT Solar Panels

- High Efficiency: HJT panels boast exceptional efficiency, reaching up to 30% for bifacial modules.

- Temperature Resilience: They perform well in high-temperature environments due to a favorable temperature coefficient.

- Bifacial Capability: HJT cells exhibit a high bifaciality factor of 92%, ideal for utility-scale projects.

- Stramlined Manufacturing: HJT modules require only 5-7 manufacturing steps, reducing production costs.

Disadvantages of HJT Solar Panels

- High Cost: HJT panels are pricier due to complex manufacturing and costly materials.

- Fragile Structure: Their thin, intricate design makes them susceptible to damage.

- Sensitivity to Moisture: HJT panels are moisture-sensitive, affecting efficiency and durability.

- Complex Production: Specialized equipment and expertise are needed for manufacturing.

- Limited Scale: Production is smaller, potentially increasing costs and limiting availability.

- New Technology: Installation and maintenance experience may be limited due to their recent introduction.

Uses of HJT Solar Cell

- Building Integration: HJT solar panels seamlessly blend into building facades, roofs, and windows, adding both aesthetic appeal and energy efficiency to structures.

- Compact Applications: In space-limited scenarios like portable solar chargers, off-grid cabins, and small boats, HJT solar panels excel due to their compact size and impressive efficiency.

- Utility-Scale Solar Farms: HJT panels find a valuable role in large-scale solar power plants, particularly in regions with abundant solar irradiance, enhancing overall efficiency for these expansive energy projects.

Parting Thoughts

The world of solar cell technology is rapidly evolving, with TOPCon, HJT, and PERC solar cells emerging as prominent contenders. Each technology brings its own set of advantages and disadvantages to the table, catering to diverse applications and preferences.

When choosing among these technologies, it’s essential to consider factors such as cost, efficiency, environmental conditions, and specific application requirements. Ultimately, the decision depends on your goals and the unique circumstances of your solar energy project.

To continue advancing in the solar industry, it is crucial for Novergy to stay informed about cutting-edge technologies. This knowledge is essential to unlock the full potential of solar power for a sustainable future.

Our experienced team is ready to assist you in finding the best solar solution through services such as site evaluation, feasibility studies, and installation.

Contact us at solar@novergy.net for more information.

FAQ’s

Q- What is the full form of PERC?

Answer- Full form of PERC is “Passivated Emitter and Rear Cell.” It refers to a type of solar cell technology designed to improve the efficiency of photovoltaic (PV) cells.

Q- What is the meaning of PV

Answer- PV stands for “Photovoltaic,” a technology that converts sunlight into electricity.