The search for sustainable and efficient energy sources has become a top priority in today’s ever-evolving world, where environmental concerns are becoming increasingly prominent. The industrial sector, a significant energy consumer, plays a vital role in shaping the future of our planet. Fortunately, technological advancements have paved the way for innovative solutions that can revolutionize energy production in industrial settings. While traditional solar panels have proven effective, a new concept is making waves in the solar industry – bifacial solar panels.

Bifacial solar panels have gained attention due to their unique design and enhanced efficiency. Unlike conventional solar panels that capture sunlight only from the front side, bifacial panels can harness energy from both sides. This innovative technology allows them to capture sunlight reflected off surfaces like the ground or nearby structures in addition to direct sunlight.

The relevance of bifacial solar panels in the context of industrial energy production cannot be overstated. Industries typically have large open spaces and utilize expansive rooftops, making them ideal locations for deploying solar panels. Bifacial solar panels take full advantage of these spaces by capturing direct sunlight and reflected light from surrounding surfaces. This increased efficiency translates into higher energy yields and a more cost-effective solution for industrial energy needs.

In this blog post, we will get to know more about the concept of bifacial solar panels, exploring their working principles, advantages, and applications in industrial settings. We will also discuss the challenges and considerations associated with their deployment.

The Science and Technology of Bifacial Solar Panels

How to do Bifacial Solar Panels Work?

The working principle of bifacial solar panels revolves around their unique design and construction. Like traditional solar panels, bifacial panels consist of solar cells made of semiconductor materials like silicon.

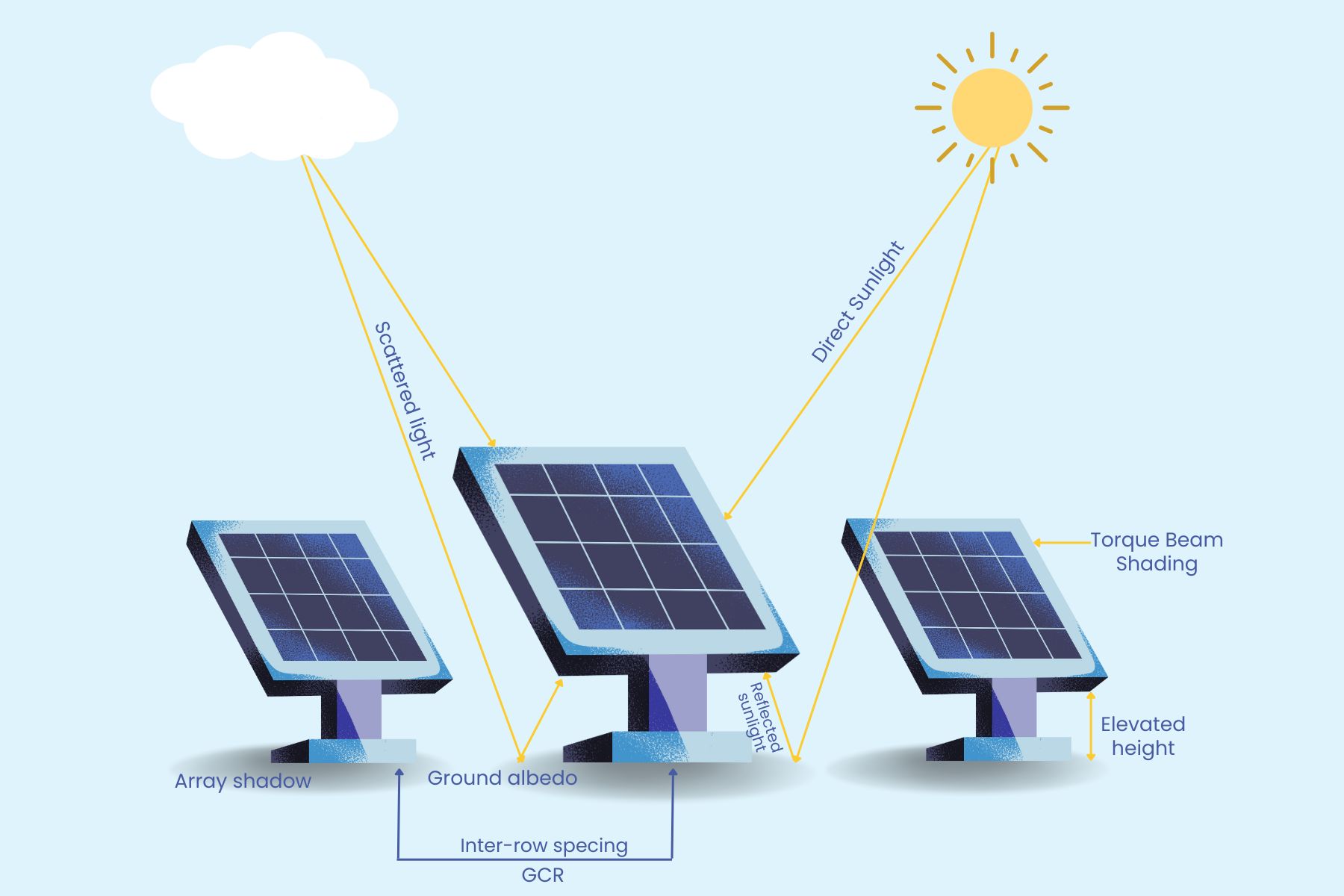

When sunlight reaches a bifacial solar panel, the front side absorbs a portion of it, just like in monofacial panels. However, bifacial panels also capture light that strikes the backside. This can happen in direct illumination from the sky or by capturing sunlight reflected off surfaces like the ground, nearby buildings, or even other solar panels in the array.

Key Components and Manufacturing of Bifacial Solar Panels

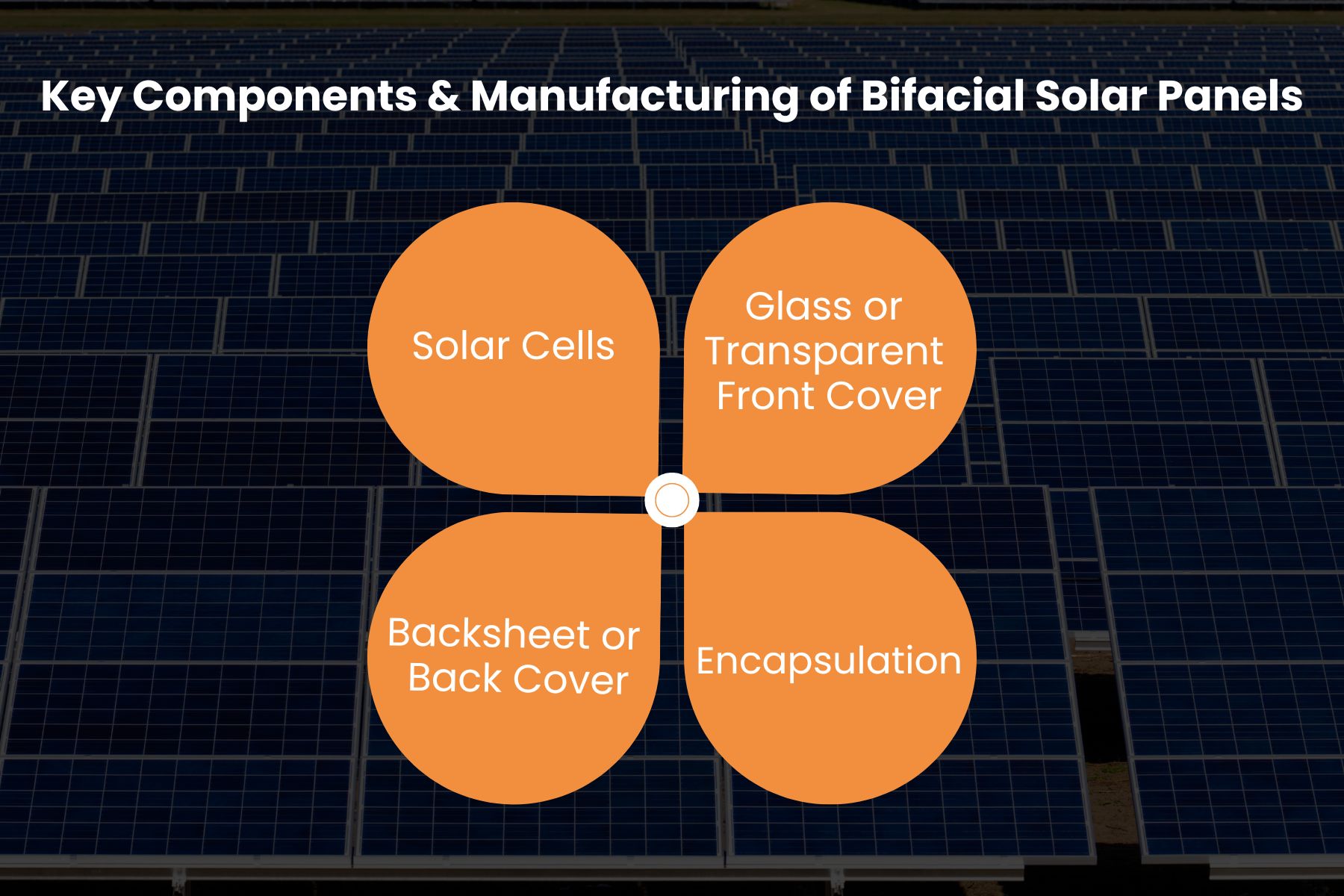

Bifacial solar panels share many components with their monofacial counterparts. The main elements include:

Solar Cells: Bifacial panels use high-quality solar cells made of semiconductor materials, usually crystalline silicon, to convert sunlight into electricity. These cells are doped with impurities to create an electric field and facilitate the flow of electrons.

Glass or Transparent Front Cover: Similar to traditional solar panels, bifacial panels have a glass or transparent front cover that protects the solar cells from external elements while allowing sunlight to pass through.

Backsheet or Back Cover: The backside of bifacial panels is typically covered with a reflective material, often a white or aluminum-colored back sheet. This surface enhances the capture of reflected light and prevents losses due to absorption by a non-reflective material.

Encapsulation: Bifacial panels are encapsulated with a durable and weather-resistant material, such as ethylene-vinyl acetate (EVA), to protect the solar cells and ensure their longevity. This encapsulation provides mechanical support and safeguards the cells from moisture, dust, and other environmental factors.

Comparison with Monofacial Solar Panels

Efficiency: Bifacial solar panels have higher energy yields than monofacial panels. The ability to capture both direct sunlight and reflected light significantly boosts their overall efficiency. Studies have shown efficiency gains ranging from 5% to 30%, depending on various factors such as installation orientation, albedo (surface reflectivity), and height above the ground.

Cost: Bifacial solar panels have decreased over the years, making them more affordable and competitive with monofacial panels. Although they may have a slightly higher upfront cost, the increased efficiency and energy production often outweigh the initial investment, resulting in faster payback periods and better returns on investment.

Durability: Bifacial panels are designed to withstand harsh environmental conditions like monofacial panels. They undergo rigorous testing to ensure their durability and resistance to temperature fluctuations, humidity, and mechanical stress. With proper installation and maintenance, bifacial solar panels can have a lifespan similar to monofacial panels.

Overview of the different types of industrial facilities where bifacial solar panels can be used:

Manufacturing Plants: Manufacturing plants often have large rooftops and expansive open spaces, making them ideal candidates for bifacial solar panel installations. These panels can be integrated into the existing infrastructure, providing clean and renewable energy to power the manufacturing processes.

Warehouses and Distribution Centers: Warehouses and distribution centers usually have vast unobstructed rooftop space. Bifacial solar panels for businesses can be installed on these rooftops to generate electricity, offsetting the energy demands of lighting, climate control systems, and other operational needs.

Industrial Parks: Industrial parks encompass a range of facilities, including research and development centers, laboratories, and office spaces. Bifacial solar panels can be deployed in such environments to meet the energy needs of the entire park or individual facilities.

Data Centers: Data centers consume substantial electricity to support operations and cooling requirements. Bifacial solar panels can be installed on the rooftops or surrounding grounds to provide a renewable energy source and reduce the carbon footprint of these energy-intensive facilities.

Logistics and Transportation Hubs: Logistic and transportation hubs, such as airports, seaports, and rail yards, have vast areas of available land. Bifacial solar panels can be deployed in these areas, providing renewable energy to power the infrastructure, lighting systems, and charging stations for electric vehicles.

Benefits and challenges of using bifacial solar panels in different types of industrial facilities

Increased Energy Production: Industrial Bifacial solar panels can generate more electricity than traditional monofacial panels by capturing direct sunlight and reflected light. This increased energy production helps industries meet their power demands more effectively.

Utilization of Available Space: Industrial facilities often have extensive rooftops and open areas that can be utilized for solar panel installations. Bifacial panels efficiently use these spaces by capturing sunlight from both sides, maximizing energy generation potential.

Cost Savings: Although bifacial solar panels may have a slightly higher upfront cost, their enhanced efficiency can result in significant cost savings over the system’s lifetime. The increased energy production translates into reduced electricity bills and a faster return on investment.

Challenges

Albedo Variability: The amount of reflected light available for bifacial solar panels depends on the albedo, which measures surface reflectivity. Albedo can vary based on factors such as ground cover, color, and angle of incidence, which may impact the overall performance of the panels.

Installation Considerations: Bifacial solar panels require careful planning during the installation process. Factors such as panel orientation, tilt angle, and the presence of shading objects must be considered.

Economic and Environmental Benefits of Bifacial Solar Panels in Industrial Settings

Economic Advantages

Increased Energy Production: Bifacial solar panels have a higher energy yield than monofacial panels due to their ability to capture direct sunlight and reflected light. This increased energy production translates into higher electricity generation, leading to potential cost savings on utility bills for industrial facilities.

Improved Cost-Effectiveness: Bifacial solar panels may have a slightly higher upfront cost than monofacial panels, but their enhanced efficiency can result in a faster return on investment. The higher energy production offsets the initial investment, leading to reduced payback periods and long-term cost savings over the system’s lifespan.

Environmental Benefits

Reduced Carbon Footprint: Bifacial solar panels provide a clean and renewable energy source, reducing the reliance on fossil fuels and lowering greenhouse gas emissions. By utilizing solar power, industrial facilities can significantly decrease their carbon footprint and contribute to global efforts in combating climate change.

Conservation of Natural Resources: Solar energy derived from bifacial panels is a sustainable alternative to traditional energy sources, such as coal or natural gas. By harnessing the sun’s energy, industrial facilities reduce the consumption of finite resources and promote the conservation of natural ecosystems.

Improved Air and Water Quality: Using bifacial solar panels in industrial settings help mitigate air pollution by eliminating emissions associated with fossil fuel combustion. This, in turn, improves air quality, benefiting both the environment and human health.

Comparison of Life Cycle Cost and Environmental Impact

When evaluating the sustainability of solar panels, it is essential to consider their life cycle cost and environmental impact. While the initial investment of bifacial solar panels may be higher than that of monofacial panels, their increased energy production and longer lifespan can result in a lower overall life cycle cost. The improved efficiency of bifacial panels often outweighs the initial cost difference, leading to greater economic benefits over time.

In terms of environmental impact, the use of bifacial solar panels generally results in lower greenhouse gas emissions and reduced pollution compared to traditional energy sources. However, the environmental benefits also depend on factors such as the manufacturing process, the materials used, and end-of-life disposal practices. Manufacturers are increasingly adopting sustainable production methods and recycling initiatives to minimize the environmental impact of solar panels throughout their life cycle.

Technical and Operational Considerations for Bifacial Solar Panels in Industrial Applications

Shading: Shading can significantly impact the performance of bifacial solar panels. Even partial shading on the front or back side can reduce energy production. Careful site assessment and shading analysis are crucial to identify potential shading sources and optimise panel placement to minimize shading losses.

Temperature: Like all solar panels, temperature affects the performance of bifacial panels. High temperatures can reduce the efficiency of the solar cells. Proper ventilation and heat dissipation measures should be implemented to mitigate temperature-related performance losses.

Soiling: The accumulation of dirt, dust, or other contaminants on the front or back side of bifacial panels can reduce their overall energy output. Regular cleaning and maintenance routines should be established to ensure optimal performance.

Best Practices for Installation, Operation, and Maintenance

Panel Orientation and Tilt Angle: Bifacial solar panels orientation and tilt angle should be optimized based on the specific location and desired energy output. Factors such as latitude, local climate, and seasonal variations should be considered to maximize solar irradiation and minimize shading effects.

Mounting and Racking Systems: Proper mounting and racking systems are essential for the stability and longevity of bifacial solar panels. The structure should withstand wind, snow, and other environmental loads while allowing sufficient airflow and minimizing shading.

Cleaning and Maintenance: Regular cleaning of both the front and back sides of bifacial panels is necessary to maintain optimal performance. Cleaning frequency may vary depending on the local climate and environmental conditions. Avoiding abrasive materials and using approved cleaning solutions are crucial to prevent damage to the panels.

Monitoring and Data Analysis: Implementing a comprehensive monitoring system allows for real-time performance monitoring and data analysis. This helps identify any issues or deviations from expected performance, enabling prompt action to maintain and optimize energy production.

Challenges and Risks in Specific Industrial Applications

Rooftop Installations: Bifacial panels installed on rooftops may face shading challenges due to surrounding structures or equipment. Proper assessment of potential shading sources and careful panel placement is necessary to mitigate performance losses.

Industrial Processes and Vibrations: Vibrations caused by heavy machinery or industrial processes can pose risks to bifacial panel installations. Structural stability, panel mounting, and racking systems should be designed to withstand such vibrations and ensure the integrity of the panels.

Dust and Particulate Matter: Industrial environments often have higher dust and particulate matter levels, which can accumulate on the panel surfaces and reduce their performance. Regular cleaning and maintenance are crucial to prevent excessive soiling.

Maintenance Access: In some industrial applications, access to the panels for maintenance and cleaning purposes may be challenging due to height, restricted areas, or safety regulations. Proper planning and provisions should ensure safe and convenient access for maintenance activities.

Future Directions for Bifacial Solar Panels in Industrial Energy Production

Innovations and Advancements

Advanced Cell Technologies: Developing advanced cell technologies, such as heterojunction (HJT) and passivated emitter rear contact (PERC) cells, can significantly enhance the efficiency and performance of bifacial solar panels. These technologies improve light absorption and minimize energy losses, resulting in higher energy yields.

Transparent Backsheets and Encapsulation Materials: Transparent back sheets and encapsulation materials allow light to pass through the rear side of bifacial panels, increasing the amount of reflected light captured. Ongoing research aims to improve the transparency and durability of these materials to enhance panel efficiency further.

Smart Tracking and Control Systems: Integrating smart tracking and control systems can optimize the positioning of bifacial solar panels to maximize their exposure to direct and reflected sunlight. These systems use advanced algorithms, weather data, and real-time monitoring to adjust panel tilt, orientation, and tracking angles for optimal energy production.

Emerging Trends and Opportunities

Floating Solar Farms: Floating solar farms, deployed on reservoirs, ponds, or other water bodies, provide an emerging opportunity to apply bifacial solar panels. The reflective nature of water enhances the performance of bifacial panels, resulting in increased energy production. Floating solar farms also help conserve land resources and reduce evaporation from water bodies.

Building-Integrated Photovoltaics (BIPV): Bifacial solar panels can be integrated into building facades, windows, and other architectural elements, offering a dual-purpose solution by generating electricity while providing shading or insulation. BIPV opens up new opportunities for industrial facilities to incorporate renewable energy generation seamlessly into their infrastructure.

Recommendations for Support

Policy Frameworks and Incentives: Policymakers should establish favorable regulatory frameworks and incentives to promote the adoption of bifacial solar panels in industrial energy production. This includes feed-in tariffs, tax incentives, and streamlined permitting processes to encourage investment and deployment.

Research and Development Funding: Increased funding for research and development initiatives focused on bifacial solar panel technologies can drive innovation, improve efficiency, and reduce manufacturing costs. Collaboration between research institutions, industry stakeholders, and government entities can accelerate advancements in the field.

Industry Collaboration and Standards: Encouraging collaboration among industry leaders, solar panel manufacturers, and developers can foster knowledge sharing, standardization, and the development of best practices. This collaboration will enable the industry to overcome technical challenges, improve system performance, and ensure quality installations.

Financing Mechanisms: Access to affordable financing options, such as low-interest loans or power purchase agreements, can facilitate the deployment of bifacial solar panels in industrial settings. Financial institutions and investors should consider offering tailored financing solutions to support adopting this technology.

Parting Thoughts

Exploring the potential of bifacial solar panels for large-scale industrial energy projects presents an exciting opportunity for sustainable and efficient energy generation. With their ability to capture sunlight from both the front and back sides, bifacial solar panels offer increased energy production and improved cost-effectiveness compared to traditional solar panels.

Bifacial solar panel technology advancements, such as advanced cell technologies, transparent materials, and smart tracking systems, enhance efficiency and performance. These innovations, coupled with emerging trends like floating solar farms and building-integrated photovoltaics, further expand the possibilities for their application in industrial settings.

When considering the implementation of bifacial solar panels for industrial energy projects, choosing a reliable and experienced partner is important. Novergy, a top choice of Solar Experts, has a proven track record of solarizing industries and corporates for over 16 years. As an integrated solar player, Novergy offers a comprehensive one-stop solution, from planning to design and execution.

By choosing Novergy, industrial facilities can benefit from their expertise, experience, and dedication to delivering high-quality solar solutions. With the potential of bifacial solar panels, Novergy offers a compelling choice for industries seeking sustainable and efficient energy solar solutions.