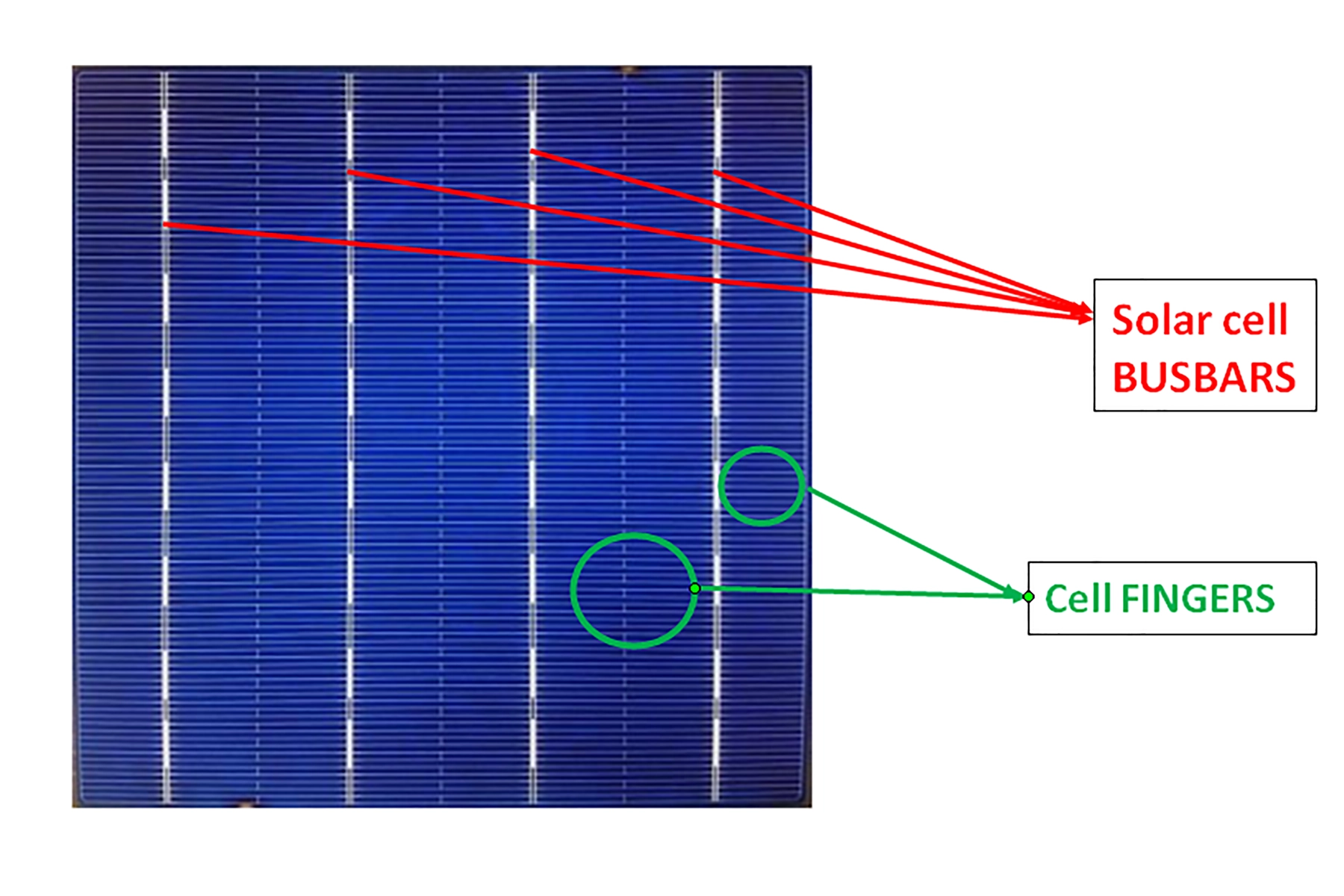

As the world looks for sustainable energy solutions, one technology that has been gaining traction is solar cell busbars and fingers. This technology is increasingly used in commercial applications to help reduce electricity costs while still providing power to industries or businesses. This article will explain what solar cell busbars and fingers are, how they work, their advantages and disadvantages, and why this energy solution is becoming popular.

What is a Solar Busbar?

Solar energy is becoming increasingly popular as people realize the benefits of using renewable energy in their businesses. One of the main components of any solar energy system is the sleeve beam, which connects the solar panels to the inverter.

A photovoltaic beam is a type of busbar specially designed for use in solar energy systems. It is a metal piece that acts as a common connection point for different solar panels made up of solar panels. The transfer bar is responsible for collecting and transmitting the direct current produced by the solar panels to the inverter, which transforms the direct current into usable alternating current.

A lead beam usually consists of a number of conductive bars or strips of copper or aluminum arranged in parallel. Each strip is connected with a bolt or clip to the positive or negative terminal of the solar panel. These individual bars are then joined to form a larger bus connected to an inverter.

The structure of a solar panel is critical to the overall efficiency and effectiveness of a solar energy system. Here, high currents and voltages must be tolerated without overheating and malfunctioning. It must also resist corrosion and other environmental factors that can degrade solar panel performance over time.

What are Solar Fingers?

Novergy is a leading renewable energy solutions provider specializing in innovative solar energy products and services. One of the company’s unique products is Fingers.

The Solar Finger is a lightweight, flexible solar panel that is the perfect solution for various applications, including curved surfaces and where space is limited. Solar Finger is made of high-quality monocrystalline solar cells with high energy conversion efficiency compared to other solar cells.

The Solar Finger is also known for its durability and weather resistance as it is designed to withstand extreme weather conditions such as extreme heat, cold, and humidity. It is also water, UV, and corrosion resistant, ensuring a long service life and low maintenance costs.

Benefits of Solar Busbar and Fingers

The solar Busbar and fingers are essential parts of the solar panel that improves its performance and durability. The busbar is a thin copper strip connecting the solar cells inside the panel. At the same time, the fingers are more petite strips that run perpendicular to the busbars, distributing power equally throughout the panel.

Here are some of the benefits of using solar busbars and fingers on solar panels:

- Better Efficiency: Solar busbars and fingers increase the efficiency of solar panels by reducing power losses due to shading, series resistance, and other factors. By distributing the current evenly, the solar fingers ensure that every solar cell in the panel receives the same amount of sunlight, resulting in optimal energy conversion.

- Better Durability: The solar busbars and fingers are made of high-quality materials that offer better durability than conventional cable systems. These components are less prone to corrosion, breakage and other damage, ensuring the long-term reliability of solar panels.

- Cost-effective: By reducing power losses and increasing panel efficiency, solar busbars and fingers can help reduce the overall cost of solar energy. With lower energy costs, businesses can save money on their energy bills by reducing their carbon footprint.

- Flexibility: The solar busbars and fingers offer greater flexibility in panel design, allowing manufacturers to create lighter, more compact, and more aesthetically pleasing panels. This feature is handy for commercial installations where space is limited.

How to Connect the Busbar and Fingers

Connecting the busbar and fingers is important in installing a solar panel system. The bus is a conductive strip that connects the solar cells and provides an electrical path for the current generated by the solar panels. The fingers are the thin wires that connect each solar cell to the busbar.

Here are some steps to connect the busbar and fingers:

- Ensure you have all the necessary tools and equipment, including a soldering iron, solder wire, flux and wire cutters.

- Clean the busbar and fingers with a cloth or brush to remove all dirt and debris. This ensures a clean and strong connection.

- Apply a small amount of flux to the busbar and fingers so that the solder flows smoothly and evenly.

- Cut the fingers to the required length with wire cutters, ensuring they are long enough to reach the busbar but not too long to overlap.

- Place your fingers on the busbar and line them up correctly. Make sure there is no overlap between the fingers.

- Use a soldering iron to heat the joint where the finger meets the busbar. Apply a small amount of solder to the joint, ensuring it covers the entire surface.

- After the solder has cooled and solidified, check the connection to ensure it is tight and secure.

- Repeat the process for all the fingers and the busbar of the solar panel system.

Connecting the busbar and fingers is essential in installing a solar panel system. By following these guidelines, you can ensure a safe and reliable connection to help your solar panel system produce maximum output for years.

Installation Considerations

There are a few things to remember when installing solar busbars and fins for your solar power system. These components are critical to the operation of your system, so it’s important to take the time to ensure they’re installed correctly.

Here are some key points to remember when installing a solar busbar and fingers:

- Correct Size: The size of the busbar and fingers depends on the size of your solar panel and the amount of current it generates. Choosing the right size for your system is essential so it can handle the electrical load without overheating or damage.

- Correct placement: Busbar and fingers must be placed where they are easily accessible and operable, protecting them from damage. When choosing a location, consider factors such as temperature, humidity, and potential physical hazards.

- Proper grounding: Proper grounding is critical to the safety and performance of your PV system. Ensure the busbar and fingers are correctly grounded to avoid electric shock and system damage.

- Correct installation: Correct installation is crucial to the longevity and reliability of the system. Ensure all components are properly and securely installed using proper hardware and connectors.

- Maintenance: Regular maintenance ensures your solar energy system works appropriately over time. Regularly inspect the busbar and fingers for wear or damage and replace any parts that show signs of wear or damage.

By considering these considerations when installing solar busbars and fingers, you can ensure that your system will operate safely and reliably for years.

Final Thoughts

The use of solar panels and fins is critical to achieving maximum energy efficiency and productivity. These components are responsible for directing the electrical current generated by the solar cells to the inverter, which then transforms direct current to alternating current (AC) for use in businesses. By using high-quality materials and designs, solar panels and fins can reduce energy losses and extend the life of solar panels.

It is important to ensure that these components are installed correctly to optimize their performance and ensure the reliability of the solar energy system. Overall, busbars and fingers play a vital role in the success and adoption of solar energy as a clean and sustainable alternative to traditional energy sources.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]